Abstract

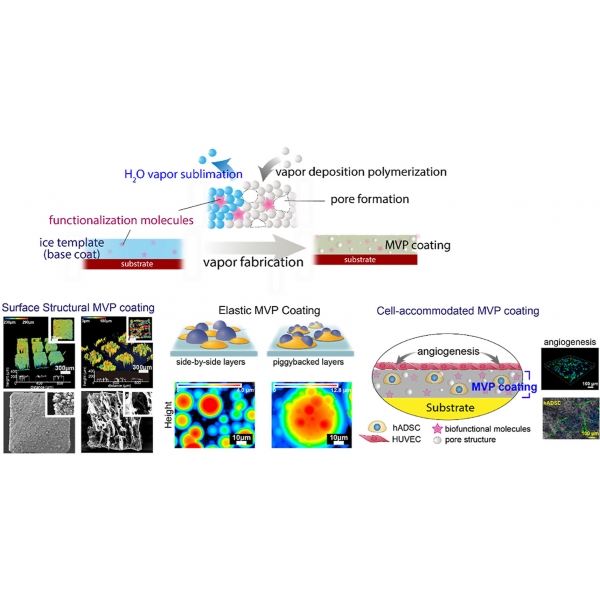

A multicomponent vapour-deposited porous (MVP) coating with combined physical and biochemical properties was fabricated based on a chemical vapour sublimation and deposition process. Multiple components are used based on their natural thermodynamic properties, being volatile and/or nonvolatile, resulting in the sublimation of water vapour (from an iced template), and a simultaneous deposition process of poly-p-xylylene occurs upon radical polymerization into a disordered structure, forming porous coatings of MVP on various substrates. In terms of physical properties, the coating technology exhibits adjustable hydrophobicity by tuning the surface morphology by timed control of the sublimation of the iced template layer from a substrate. However, by using a nonvolatile solution during fabrication, an impregnation process of the deposited poly-p-xylylene on such a solution with tuning contact angles produces an MVP coating with a customizable elastic modulus based on deformation-elasticity theory. Moreover, patterning physical structures with adjustable pore size and/or porosity of the coatings, as well as modulation and compartmentalization to introduce necessary boundaries of microstructures within one MVP coating layer, can be achieved during the proposed fabrication process. Finally, with a combination of defined solutions comprised of both volatile and nonvolatile multicomponents, including functional biomolecules, growth factor proteins, and living cells, the fabrication of the resultant MVP coating serves devised purposes exhibiting a variety of biological functions demonstrated with versatility for cell proliferation, osteogenesis, adipogenesis, odontogenesis, spheroid growth of stem cells, and a complex coculture system towards angiogenesis. Multicomponent porous coating technology is produced based on vapour sublimation and deposition upon radical polymerization that overturns conventional vapour-deposited coatings, resulting in only dense thin films, and in addition, the versatility of adjusting coating physical and chemical properties by exploiting the volatility mechanism of iced solution templates and accommodation of solute substances during the fabrication process. The MVP coating and the proposed fabrication technique represent a simple approach to provide a prospective interface coating layer for materials science and are attractive for unlimited applications.

KEYWORDS: Vapour sublimation and deposition, Multicomponent, Physical structuring and patterning, Surface modification, Biointerface coating.png)